What is the minimum unit of a project? It’s the room. But what if we could standardise this minimum unit by applying innovation from different sectors, thus providing a solution suitable for any type of construction need? The answer to these questions is ROOM2030, an architecture startup that emerged in Spain in 2018 with the goal of prototyping the housing model and reducing the complexity of building, without sacrificing sustainability.

The origins of ROOM2030

“Our point of reference was the automotive world, where mass production that reduced costs without reducing efficiency has been achieved,” explains Sergio Baragaño, architect and CEO of ROOM2030. “[In architecture], the room replaces the car, where options are tested and tried out to reach a scalable model of industrialised living spaces,” he explains.

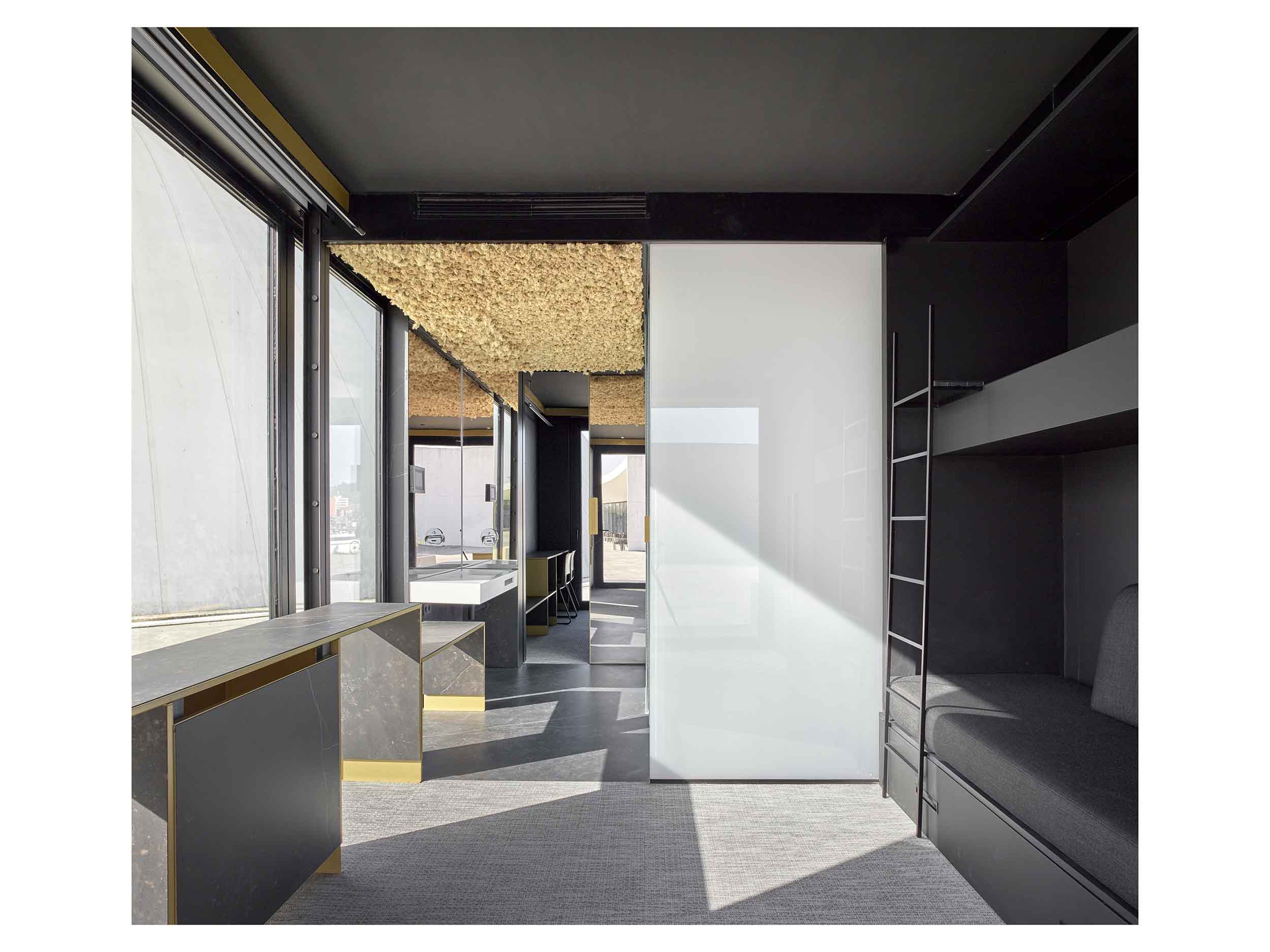

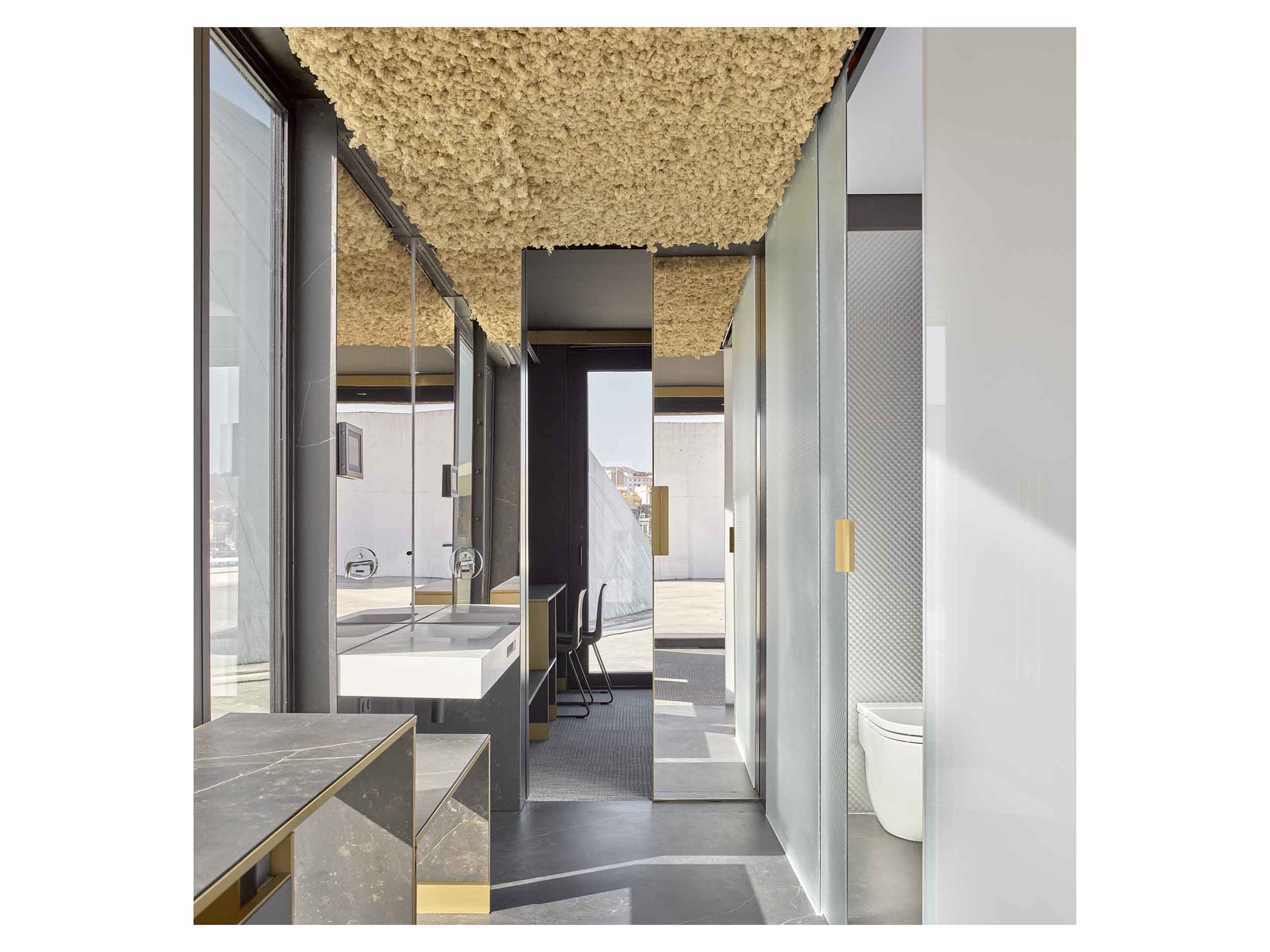

The seed for the ROOM2030 consortium was planted with the testing of a luxury hotel housing concept at the Living Lab, an initiative established by Baragaño at the Niemeyer Centre. Encouraged by the positive market response, the startup was subsequently founded. “Although the initial prototype targeted high-end spaces, the ultimate goal is to offer solutions across various sectors, encompassing both medium and high-quality standards. This involves standardising processes and achieving economies of scale through the production chain,” he explains.

Three industrialised living spaces

Following the automotive industry model, three types of “chassis” (rooms) were established. These were then used to configure a series of models that can be used to create a residential building. Three room sizes are currently offered in ROOM2030, each of which functions as products in its own right: 25m2, 45m2 and 55m2.

These minimum construction units are customised and scaled to be finished at the factory and can even come already furnished. This significantly reduces the working time at the final location, meaning homes are being produced in as little as twelve weeks.

The impact on the site is also reduced thanks to lighter foundations, the result of a dry construction system that doesn’t need water or generate waste. Finally, specific certifications required by developers or clients are added. It’s a win-win for the entire value chain.

The materials in the rooms of the future

ROOM2030 is a fablab in which a very practical approach is used to test “how different products can be adapted, and thus act as a source of innovation for new solutions or even joint solutions with other agents“, explains Primitivo Vizoso, head of Open Innovation at Finsa, one of the companies that make up the startup consortium. Vizoso explains that for the entities that make up the initiative, it is also “a way of exploring new business models beyond the usual organisational channels, with all the freshness and agility that that brings”.

ROOM2030’s CEO describes wood as “a natural product that fits perfectly into the startup’s philosophy of circularity, not only because it does not emit CO2, but also because of its capacity to store it and its lightness for transport and assembly, in addition to all the ornamental qualities it offers for interiors”. The star product coexists in these spaces with other materials such as steel or concrete.

The challenges facing ROOM2030

ROOM20230’s goal is to “change the construction system and be a leader when it comes to revolutionising the way structures are built,” says Baragaño. The startup is tackling various challenges, such as decarbonisation through reforestation, including a project in Extremadura with Quercus, and high-rise construction through industrialised modules that can be scaled in during manufacturing.

ROOM2030 sees this last challenge as the key to a great exponential leap in the sector that will lead to reduced costs and faster construction times. In other countries, including England, there are already 35-floor buildings that have been built using this approach. With this goal in mind, three lines of work are being developed to support these advancements:

- Product development for specific needs: office, home-office etc.

- Digitalised manufacturing processes, a project financed by the Principality of Asturias.

- A digital platform that connects the entire value chain, from manufacturer to end user.

We will keep a close eye ROOM2030 and the different projects and products that emerge from this great example of collaboration between companies from different sectors working together for a common good: to improve construction and reduce its impact on the environment.